Annual Research Progress of the Oil and Gas Flow and Solid Control and Production Completion Laboratory in 2023.

In 2023, the laboratory continued innovative research in flow and solid control, supporting the efficient development of oil and gas energy.

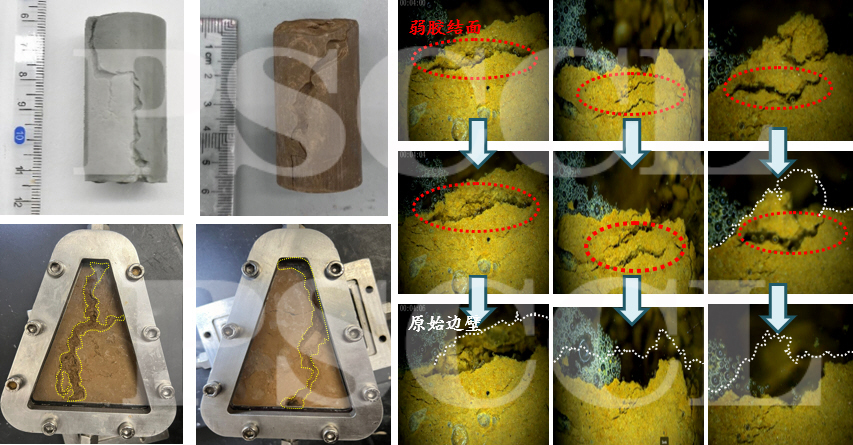

Progress 1: Simulation of Sand Production Process and Microscopic Mechanisms of Mud-Sand Exfoliation in High Clay-Content Weakly Cemented Reservoir Cores

Based on previous visual simulation studies, experimental research was conducted on the mechanisms and patterns of sand production in high clay-content shallow gas reservoirs. Under gas-water co-displacement conditions, noticeable sand production was observed in both real reservoir cores and visual thin-section models. The sand production pores and throats had small equivalent diameters, high tortuosity, and prominently irregular walls. By analyzing the evolution of sand production patterns, the phenomena of particle retention blockage and production clearance in weakly cemented, high clay-content reservoirs were examined. This revealed the essential reasons for the increase, sharp decline, and equilibrium state of displacement pressure. At the microscopic level, it was found that high clay-content reservoirs have complex micro exfoliation units, with both single particle and cluster mud-sand forms, and that cluster mud-sand/weak cementation face exfoliation occurs easily. Both single particle/cluster mud-sand competitive exfoliation mechanisms and concurrent exfoliation mechanisms exist in these types of reservoirs, leading to a more branched and complex sand production pattern. This research progress provides theoretical guidance for subsequent numerical simulations of sand production and evaluations of sand control methods in high clay-content, high water-content, extremely weakly cemented reservoirs.

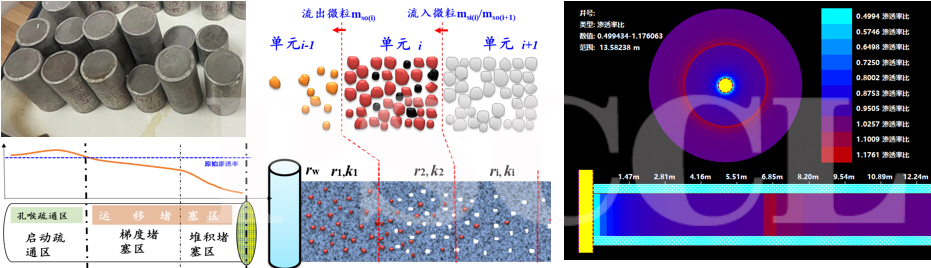

Progress 2: Experimental and Numerical Simulation Methods and Techniques for Particle Migration in High Water-Cut Loose Sandstone Reservoirs

In the laboratory, tests were conducted on actual and artificial cores with varying water saturations in loose, high water content near-well reservoirs. These tests included rock strength measurements and experiments on changes in porosity and permeability characteristics. The mechanisms and patterns of how high water content affects reservoir strength, porosity and permeability properties, and particle detachment conditions were clarified. A predictive model for particle migration and its impact on reservoir fluid supply was developed under conditions of high water content with micro-sand/mud. Systematic pattern analysis was conducted. Additionally, a simple and fast simulator for predicting particle migration was created. This simulator can predict the critical conditions and the extent of particle migration under given reservoir and well production conditions. It quickly estimates the permeability damage within the migration zone and calculates the additional skin factor caused by permeability damage and its impact on productivity. The "dislocation migration and gradient blockage" mechanism was proposed to explain the reduction in fluid supply capacity due to particle migration from the near-well reservoir to the wellbore. The simulation of particle migration and its impact on productivity was realized, enabling the evaluation and analysis of its patterns. This guides decision-making and optimization of macroscopic production strategies at the reservoir level.

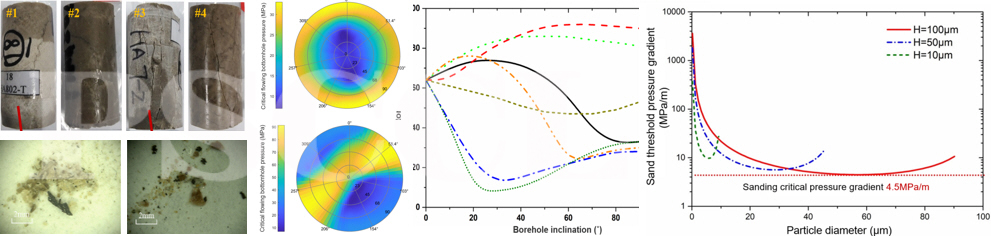

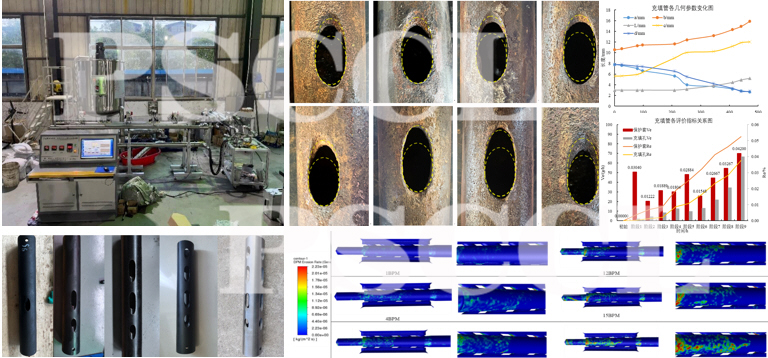

Progress 3: Simulation and Prediction Methods for Macroscopic Instability and Microscopic Mud-Sand Production in Fractured Carbonate Reservoirs

To address the issue of wellbore macroscopic instability and mud-sand production in deep fractured carbonate reservoirs, physical simulation experiments and numerical simulation studies were conducted. These studies revealed the mechanisms of wellbore macroscopic instability under different wellbore structures and production conditions, and developed numerical simulation and prediction methods. Through production flow simulation experiments with macroscopic unstable cores, the mechanisms and controlling factors of induced fracture fill instability and production were revealed. Based on experimental research, a new method combining a geomechanical model and a microscopic sand production model was proposed to predict wellbore instability, analyze the degree of instability, and determine the critical conditions for microscopic mud-sand production. The critical state and instability regions predicted by the model were generally consistent with engineering descriptions. Based on the prediction results, measures for managing and preventing wellbore instability in carbonate reservoirs were proposed, providing decision-making support for preventing instability in new wells and managing instability in old wells.

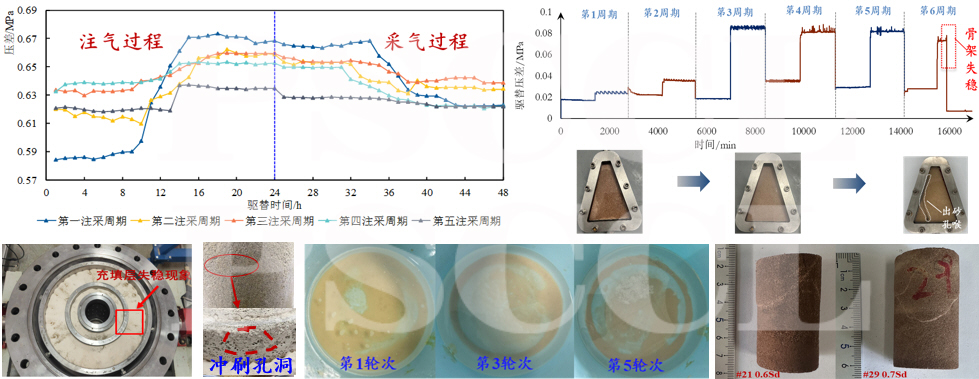

Progress 4: Mechanism of sand release, sand release prediction and prevention and control mechanism of high-intensity alternating injection and extraction in gas storage reservoirs

The periodic high-intensity injection and withdrawal production in underground gas storage causes dynamic damage to the reservoir due to the "three alternations" of reservoir stress-strain, fluid flow direction, and gas-water interface migration. This leads to complex instability and sand production behaviors. Laboratory tests using actual gas storage reservoir cores and large-scale simulated cores were conducted to study changes in rock microstructure, rock mechanical properties, and basic physical properties under alternating injection and withdrawal conditions. These tests revealed the changes in the microstructure of reservoir sand grains, the mechanical damage patterns of cores under cyclic conditions, and the variations in core physical properties. Using a large-scale alternating injection and withdrawal sand control system instability mechanism and control experimental simulation system, the instability mechanisms, modes, and identification methods of gravel layers and coated filling layers during alternating injection and withdrawal were uncovered. This provides theoretical and technical support for efficient and safe production in gas storage reservoirs under alternating injection and withdrawal conditions.

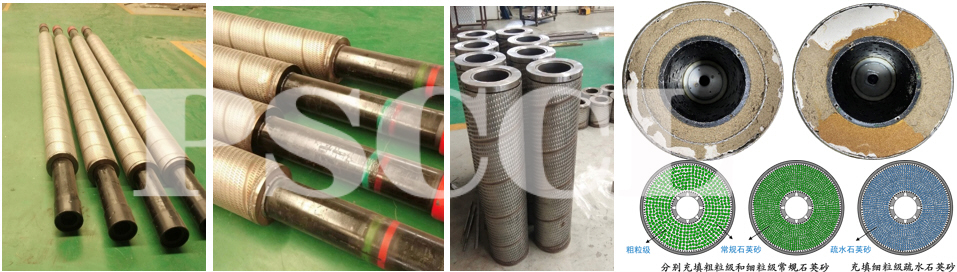

Progress 5: Novel Pre-packed Screens for Natural Gas/Hydrate Argillaceous Silt and Their Efficient Sand Control and Flow Mechanisms

Focusing on the gas-water sandcarrying flow conditions in natural gas wells and gas hydrates, as well as the sand production characteristics of argillaceous silt, multi-layer, multi-grain composite pre-packed screens and modified composite cavity pre-packed sand control screens were developed. These innovations address the conflict between sand control and productivity under high argillaceous content conditions, achieving long-term and efficient sand production control. The novel screens feature an innovative design along the axial and radial directions of the screen, incorporating multi-layer, multi-grain composite pre-packed structures and modified composite cavity pre-packed structures. A prototype of the new screen was successfully trial-produced. Physical simulation experiments were conducted to compare and analyze the comprehensive sand control performance of conventional pre-packed screens versus the new pre-packed screens. These experiments revealed the sand control and flow mechanisms of the staggered cavity and multi-grain filling. The structure of the new pre-packed screens was optimized and finalized, resulting in two new design methods for pre-packed screens. These advancements support effective long-term sand production control in argillaceous silt hydrate reservoirs.

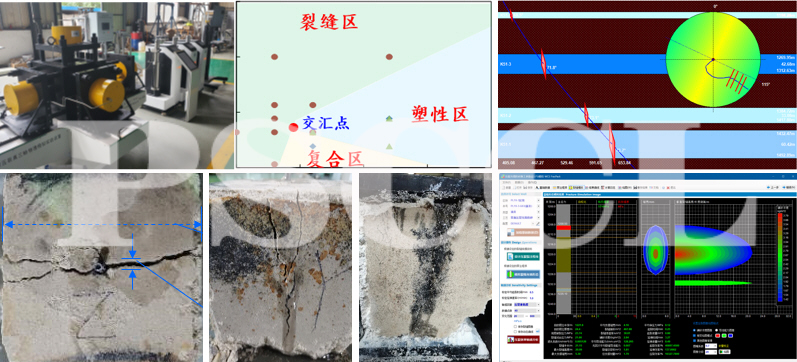

Progress 6: Mechanism and simulation of fracture initiation in weakly cemented reservoirs of loose sandstones and optimal design method for fracture filling

Through true triaxial fracturing simulation experiments on loose sandstone reservoirs, the mechanisms and influencing factors of fracture initiation and propagation in loose sandstone were revealed. This research provides a systematic understanding of how reservoir cementation strength, in-situ stress conditions, and construction parameters affect plastic extrusion damage and fracture opening modes. The study developed methods for predicting the geometric morphology of fractures and designing fracturing and filling processes in loose sandstone reservoirs. It also involved the development of proprietary software systems to achieve refined design of on-site construction parameters (filling displacement, pump pressure, injection volume) and operation scales. Rapid design of fracturing and filling parameters for different formation characteristics was conducted, and recommended practices for fracturing and filling under various formation conditions were established. The research covered a full chain of design and simulation, including the combination and optimization of fracturing and filling design levels, reservoir damage mode identification, fracture parameter design, fracturing process simulation and optimization, evaluation of fracturing and filling productivity, and staged fracturing optimization in open-hole horizontal wells. This comprehensive approach supports the implementation of fracturing and filling processes in loose sandstone reservoirs, improving sand control and production enhancement effects.

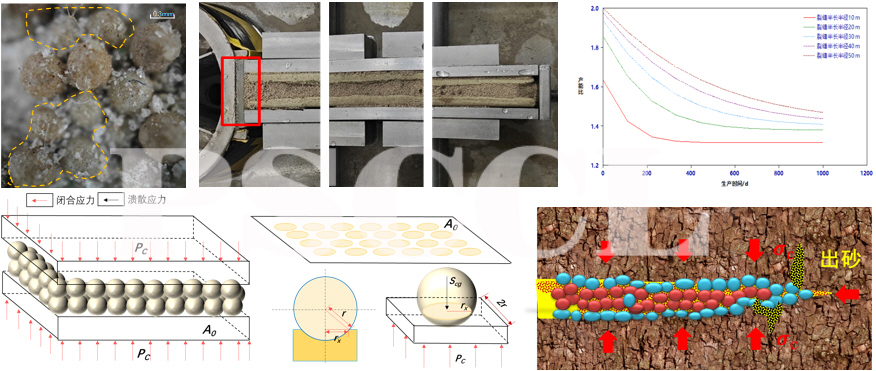

Progress 7: Dynamic Production Capacity Evaluation of Loose Reservoir Fracturing Closure Compaction/Sand Proppant Embedding/Formation Sand Plugging Synergistic Effects

Fracturing and filling is the leading technology for controlling sand production and increasing output in medium to high permeability loose sandstone reservoirs. For production conditions after the completion of fracturing and filling wells in loose sandstone reservoirs, experimental simulations have been conducted to study the dynamic changes in fracture permeability, conductivity, and the synergistic effects of fracturing closure compaction, proppant embedding, and formation sand intrusion and plugging. A predictive model for dynamic fracture permeability changes has been developed, and a dynamic production capacity evaluation method under multi-synergistic effects of fracturing and filling wells has been established. Through numerical and experimental simulations, the study reveals the control mechanisms and patterns of various complex conditions—such as reservoir permeability, closure pressure, proppant properties, sand production strength, sand particle size, clay content, fluid properties, and production pressure differential—on the production capacity of fracturing and filling wells. This provides crucial guidance for optimizing sand control construction parameters and enhancing production effectiveness in loose sandstone reservoirs.

Progress 8: Erosion Damage Mechanisms, Simulation, and Damage Prediction Methods for Lateral Outflow Holes in Filling and Fracturing Construction Strings

To address the issue of severe erosion

damage to the lateral perforations of the multi-layer filling/fracturing

construction string, which significantly limits tool lifespan, erosion flow

evaluation experiments and erosion simulation were conducted. The erosion

damage mechanisms and patterns were analyzed, leading to the establishment of

erosion damage evaluation methods and damage rate prediction models. It was

revealed that the erosion damage of filling hole lateral perforations goes

through four stages: coating disappearance, end face wear, rebound erosion, and

morphology extension. Three erosion damage mechanisms were identified: tip

lateral cutting, end face lateral cutting, and particle rebound frontal

erosion. The developed lateral outflow hole erosion damage evaluation method

and damage rate prediction model can accurately assess the erosion damage speed

of complex structured lateral perforations, the erosion damage amount at a

given time, and the relative damage degree. Additionally, they can quickly

predict the erosion damage rate and lifespan of porous structures based on

perforation structural parameters and erosion flow rates. This provides a

quantitative basis for predicting erosion damage in fracturing filling tools,

supporting their optimized design and lifespan improvement.

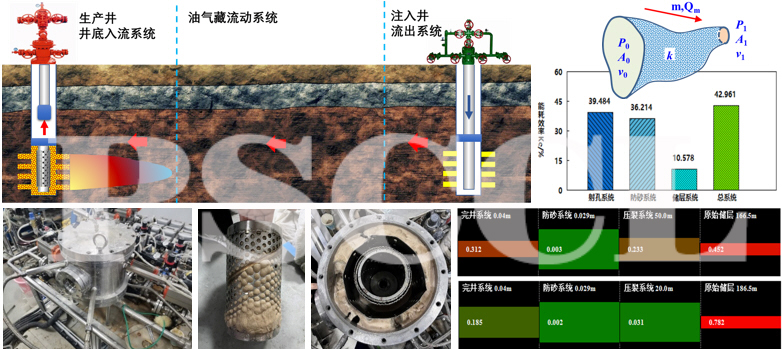

Progress 9: Evaluation of Production Energy Consumption and Optimization of Energy Efficiency Improvement Techniques for Near-Well Reservoir Completion/Sand Control/Fracturing Systems

To address perforation

completion, sand control, and fracturing technologies for high, medium, and low

permeability reservoirs, this study developed evaluation indices and

characterization methods for energy consumption in the near-well reservoir flow

system during production. Using a multifunctional sand control performance

evaluation device with unidirectional and radial flow modules, experiments on

pressure drop and energy consumption in perforation completion, sand control,

and reservoir stimulation systems were conducted. The models for calculating

the pressure drop and energy consumption in perforation/sand control/fracturing

systems were fitted and corrected. Based on the energy consumption and

efficiency indices during the production cycle of perforation completion, sand

control, and reservoir stimulation systems, the study established quantitative

relationships between energy consumption indices and process parameters. By

using energy consumption density as an indicator and multi-system coordination and

balance as the principle, a method for the synergistic optimization of energy

efficiency in sand control and production enhancement process parameters was

developed. The Waterflood Efficiency Optimization Software (WEEOpt) for

near-well productivity enhancement in waterflooding reservoirs was developed to

provide a basis for optimizing development technologies under energy

consumption constraints, supporting the green, low-carbon, and high-quality

development of oil fields.

Progress 10: Ongoing Development and Application of the Sandcontrol Office System for Flow-Solid Control and Integrated Decision-Making in Extraction and Completion

Sandcontrol Office is a comprehensive software platform that integrates various functions, including the acquisition of rock mechanics parameters for different types of geological energy reservoirs, sand production simulation and prediction for oil and gas wells, evaluation and optimization of sand control schemes, comprehensive well completion condition simulation and integrity assessment, sand control completion parameter design, production system design and analysis for sand-carrying wells, sand control completion productivity prediction and evaluation, effectiveness assessment of sand control measures, gravel packing simulation and design for horizontal and high-angle wells, sand control database system, and related calculation toolkits. This system can handle nearly all management, calculation, analysis, evaluation, design, and office automation tasks related to sand control completions in oil and gas wells, covering all current sand control technologies. It provides oil and gas well sand control engineers with a complete platform for sand control work, offering comprehensive solutions tailored to the geological characteristics of different oil and gas reservoirs.

The 2025 version of the

Sandcontrol Office software has been updated and is about to be distributed and

upgraded. The new version integrates the latest simulation, computation, and

design technologies developed by the PSCCL laboratory in recent years, providing

users with more comprehensive solutions for flow-solid control and well

completion.