The

production of sand (also known sanding) is an universal phenomenon that occurs during

the hydrocarbon production in the weakly consolidated sandstone reservoirs. Sand

production may cause many undesirable problems including, but not limited to, filling

and blocking of wellbore, wellbore collapse, plugging of perforations or

flowlines, erosion failure of downhole and surface facilities, and additional

cost of remedial and cleanup operations (Rahmati et al. 2013). Nowadays,

it has been well accepted that certain amount of sand production can be helpful for improving near-wellbore

formation conductivity and productivity. But poor management or uncontrol of sand

production can lead to problems of sand overproduction with severe consequences

aforementioned (Garolera et al. 2019). For

decades, the problem of sand production has been approached with the use of

sand avoidance techniques, called sand control methods. These methods involve mechanical

method to physically block sand grains with screen or gravel packing, and

chemical method to reconsolidate the formation and prevent sand from flowing

with resin or other chemical agents (Dong et al. 2009, Parlar et al. 2015, Garolera et al. 2019).

As

the foundation of sand control design, sand production prediction is extremely

important work to clarify the sanding mechanism and law, which can offer strong

support for sand control optimization (Dong et al. 2015,2017). Over the decades, due to its importance in hydrocarbon

production industry, systematic efforts have been made to develop the numerical

methods for sand production prediction. The early studies on sand prediction approach

focused on the macroscopic sand production law (Weingarten et al. 1995; Nouri et al. 2002; Papamichos et al.

2018), which mainly depended on the solid failure mechanics

of compression, tension and shear effect (Risnes et al. 1982; Van Den Hoek et al. 2000). These methods concern the use of rock

strength, formation stress distribution and failure criterion of rock to calculate

the critical drawdown pressure for onset of sand production (Wan et al. 2004; Rutqvist et al. 2012). This type of sand prediction models can

only answer under what production condition (production

rate or bottomhole flowing pressure) the wells begin to produce sand, but is

unable to predict the sand production rate and volume quantitatively (Crook et al. 2003; Dong et al. 2017). In order to make volumetric

predictions of sanding, series of numerical models for sanding simulation and prediction

were developed continuously. The early sand production and erosion models for

predicting sand production in unconsolidated formation was presented by

Vardoulakis et al (1996). This mathematical model was based on mass balance of

the produced solids and flowing fluid in porous media, and can be used to

predict the sanding rate with production time. This model was developed

furtherly by Papamichos et al (1998) by coupling the poro-mechanical

behavior of the solid-fluid system with the erosion behavior of the solid

matrix due to fluid flow. Then, further improvements were made by Papamichos et

al (2010,2019) and

Gravanis (2016). This group of models

provide mainly an access to predict sand production rate based on flow-coupling

and stress analysis. In recent years, the new developed sanding simulation

methods, in general, are categorized as continuum and discontinuum approaches. In the continuum approach, cemented granular materials of

sandstone formation are treated as continuous matters in deriving the governing

differential equations (Morita et al. 1989; Nouri

et al. 2006, 2007; Papamichos et al. 2010; Hussein et al. 2018).

This type of sanding prediction models depends on the presupposition of

continuous and homogeneous medium of formation. Garolera

et al (2019) presented a micromechanical

approach based on zero-thickness interface elements for modelling advanced

localization and cracking states of cemented granular materials. The increase

in computational resources due to discretization of the grain area is

compensated by modelling the remote area with continuum finite elements. The

model is capable of modelling localization of deformation, disintegration and

cracking of cemented rock formation. However, the heterogeneity is not fully

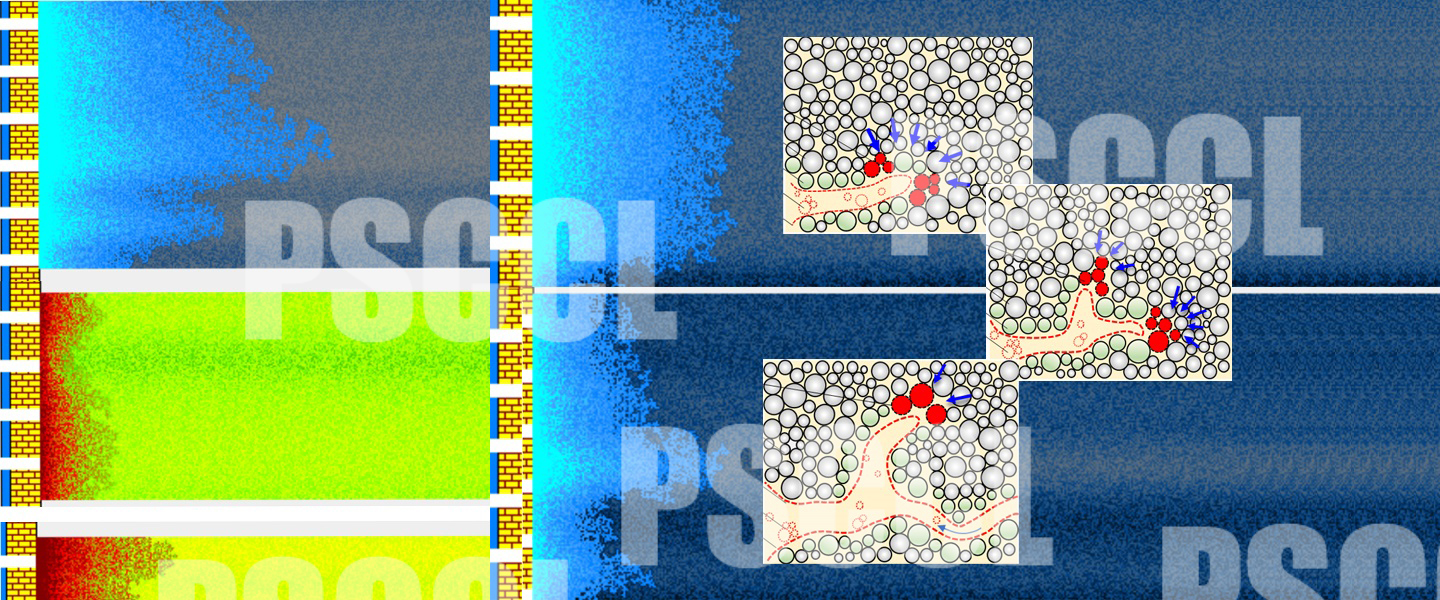

considered in his model. The typical method of discontinuum approach is discrete element method (DEM)(O’Connor et al. 1997; Wan et al. 2003),

which is an useful access to simulate sand production, especially to understand

the mechanism of sanding (Rahmati et al. 2013;

Ghassemi et al. 2015; Han et al. 2016). However, it’s difficult to describe the heterogeneity of rock properties and its

application is limited in large scale simulation (Climent et al. 2017). To date, similar studies also have been done to

sand production prediction for gas hydrate bearing sediments with particular

consideration of hydrate decomposition (Cheng et

al. 2010; Li et al. 2013; Pinkert et al. 2015; Uchida et al. 2016; Kajiyama et

al. 2017; Dong, et al. 2019). Generally speaking, the prediction results

of above-mentioned continuum and discontinuum methods just show the macroscopic

sanding law with oil or gas production, but are not capable to describe the

sanding pattern and cavity shape of near-wellbore formation and their

heterogeneity.

In an actual well in weakly

consolidated sandstone reservoir, after a long-term production with sanding,

the continuous removal of solid from formation tends to cause the obvious

change of microscopic structure and porosity-permeability properties (Wan et al. 2003; Dong et al. 2017,2020). From

the engineering point of view, one of the interesting issues the petroleum

engineers care is what the sanding pattern and cavity shape would be after a

given period of sanding production, the recognition of which can essentially

help to optimize sand control design. Unfortunately, although major

improvements have been achieved in the past decade, it’s still a difficult and

challenging issue to describe the sanding pattern and cavity shape of an actual

sanding well before sand control design and implementation. What we just know

is that the sanding cavity may be very complex and non-homogeneous depending on

the characteristic of formation properties (Dong et

al. 2020).

In this work, we construct a new particle-scale microstructure model of weakly consolidated formation core and the subsequent numerical methodology to simulate the microscopic sanding process during production. The proposed microstructure model describes the heterogeneity of formation using random function, considering the particle size distribution (PSD) curve, well logging data, formation stress distribution and dynamic rock strength. This integrated methodology provides a new access to predict and describe the sanding cavity shape of an oil well after long-term sanding production, which is essentially meaningful for sand control design optimization.

Sand

production in weakly consolidated sandstone reservoir is a complex phenomenon.

The sanding performance depends on various factors involving sand grain size,

grain sphericity and inclination angle, intergranular cementation strength,

stress distribution, fluid properties, fluid flowing field, etc. We present a microstructure model in this work as an effective

access to reconstruct the structure of formation near wellbore, which can

reproduce the complex behavior of intergranular aggregation and offer the

foundation for subsequent sanding simulation. The proposed microstructure model

not only fully utilizes the limited information such as PSD curve, well logging

data and principal stress, but also specifically take the heterogeneity and randomness

of reservoir properties in account.

Based on the microstructure model, the proposed sanding simulation approach is capable of simulating the microscopic sand production process, depicting sanding cavity characteristic and predicting sanding law quantitatively. In particular, the simulation method and programs can be implemented to visually present the whole process of sand production and sanding cavity propagation. From the simulation results of series of case analysis, the sanding performance shows some interesting and special characteristics corresponding to the heterogeneity and randomness of reservoir properties characterized by the microstructure model. Sensitivity analysis results show that sanding frontier and ESC radius decrease with increasing average cohesion strength and increase with increasing average liquid production rate. For weakly consolidated sandstone reservoir with different properties, it is found that three typical sanding patterns involves PLS, PWS and CCS patterns. In an actual well, the sanding pattern may be the combination of two or three of the typical patterns. The present simulation method and program can be used to predict the sanding cavity shape along the well axis and identify the production profile with severe sanding. This will help to determine the focus target for sand control implementation and improve its effectiveness considerably.